Today’s microscopy systems capture complex systems with high precision, making them vital to life science researchers seeking to understand biological mechanisms. However, as with any lab equipment for research, your microscope must perform consistently to yield reproducible data.

This presents a challenge as microscope equipment and image analyses become increasingly complex.

In this post, we take a closer look at the importance of monitoring microscope performance and share how analytical tools can help identify issues that introduce bias in your results.

How Bias Can Creep into Experimental Data

Bias can easily creep into your experiment from multiple sources. Take morphological analysis for example. When seeking to measure changes in cell structure, you must take images and measure morphological differences. Even if your microscope is performing as it should, bias in your images and the subsequent results can occur from sample preparation or biological variations in the specimen. This poses a challenge for acquiring accurate, reproducible data.

Now consider if this task was undertaken using an uncalibrated microscope. Further bias would be introduced to the image from the microscope itself, and subsequent measurements would lack accuracy and precision. As a result, it would be difficult to reproduce the same dataset if you performed the same experiment again.

This a serious problem for researchers looking to publish their experimental data. Let’s say a reviewer requests that you repeat an experiment. Without calibrated instrumentation, you could face an uphill struggle to achieve comparable results.

While there’s little to be done to curb biological variations in a specimen, there are ways to monitor your microscope’s performance and reveal where the bias is being introduced to your imaging and measurements. We’ll explore these options further on after we review the errors and bias found in quantitative measurements.

Errors in Quantitative Measurements

A variety of different quantitative analyses can be performed using a microscope. Most quantitative applications include measurement and comparison of either fluorescence intensity or spatial changes within an image.

Every quantitative measurement contains some amount of error or bias. This error may be introduced by the specimen or the microscope, and it can manifest as inaccuracy and/or imprecision in measurements. While inaccuracy yields consistent incorrect measurements, imprecision drives variance in repeated measurements. Both are the enemy of reproducible data.

In the past, many image analysis studies relied on manual measurements for quantitative analysis. Over the last two decades, we have witnessed a trend towards bioinformatic image analysis, as well as software tools including AI programs that can automate measurements and massively increase throughput. Because of this, the amount of data generated in quantitative microscopy experiments has reached new heights.

As researchers produce more and more images per experiment, and those images are fed into complex models to analyze them and extract the relevant information, it is imperative to start with the most high-quality, stable set of images possible. When imaging takes place over several days, a microscope with unstable performance during that time will certainly introduce wide inconsistencies in your data. No matter how powerful your analytical software might be, the ground truth in your images will have the biggest effect on the consistency and reliability of your data.

It's not just greater throughput and analysis software that creates opportunities for error. Today’s microscopy systems are more complex than ever with various optical, mechanical, and electrical components. The opportunity for misalignment, malfunction, or failure in these instruments increases as the number of complex components rises.

If the complexity of microscopy systems adds further potential bias in your data, what can be done to monitor the performance of your microscope and to make sure you have consistency in your results?

Tools and Support to Monitor Microscope Performance

When you first purchase a microscopy system, leading manufacturers such as Evident deliver a microscope with stringent, highly defined performance parameters. During installation, a precise protocol is followed to make sure the microscope meets factory standards.

Over time, some performance metrics might waiver outside of an acceptable range, and this is why a performance analysis of your microscope is so important. You need to make sure that your microscope is performing consistently—no matter if it’s one day, one month, or one year after your purchase.

Traditionally, gaining insight into microscope performance has been a laborious process, often involving the construction of a calibration curve of output intensity against percentage transmittance with calibration toolkits. Troubleshooting specific parameters (e.g., resolution or homogeneity), has also been challenging in the past, with different troubleshooting tools required to detect specific malfunctions.

Built-In Microscope Performance Monitoring Tools

Today, there are simpler, more rapid solutions that take the hard work out of monitoring microscope performance. Consider the following example. During longitudinal time-lapse microscopy, some microscope systems are prone to fluctuations in performance over long periods. This yields time-lapse images of varying quality.

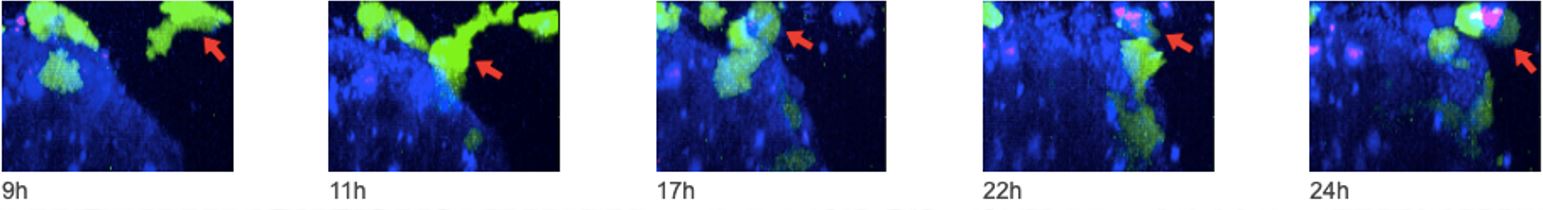

One contemporary solution—the FLUOVIEW™ FV3000 confocal laser scanning microscope—features stable laser power for these experiments. An optical laser intensity monitoring and feedback control system in the scan unit provides stable excitation intensity during prolonged time-lapse studies. This is demonstrated in the time-lapse images below (Figure 1).

Figure 1. Time-lapse images taken with the FV3000 confocal microscope. Natural killer (NK) cell line KHYG-1 (green) changing shape while attacking and killing HT-29 tumor cells labeled with cetuximab (blue). Propidium iodide (PI) uptake (red) indicates cell death.

External Microscope Performance Monitoring Tools

In addition to built-in microscopy solutions for performance monitoring, there are a number of external solutions that can help microscope users and manufacturers alike make sure that microscopy equipment is functioning optimally. Argolight is a company that specializes in microscope quality control solutions. The company has designed a range of quality control slides and accompanying software that can detect even minor fluctuations in microscope performance.

Argolight’s performance analysis solutions come in the form of slides or microwell plates. They can be used for quality control in a wide range of microscope systems, including fluorescence microscopes. These solutions represent a valuable starting point for researchers who are unsure about their microscope’s performance.

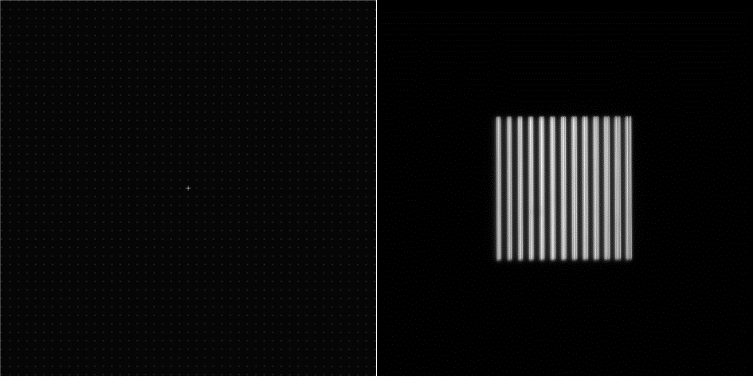

Figure 2. Two of the 16 fluorescent patterns are incorporated into each Argolight HM slide. Left image: the field of rings pattern for inspecting image flatness. Right image: the gradually spaced lines (vertical) pattern for inspecting resolution.

But how do they work?

In short, the slides contain a highly-defined geometrical fluorescent design with a matrix of focal points (examples outlined above in Figure 2). These slides are imaged, and then the images are analyzed by the software. Notably, the software can detect any bias in the microscope’s performance and detect the degree of bias for each parameter. If any value is outside the acceptable range determined by the user, this information can be sent back to the manufacturer or core facility in the form of a concise error report.

Streamline Your Microscope Troubleshooting to Stay on Track

Rapid microscope quality control solutions such as those from Argolight can benefit both the user and the manufacturer. For instance, suppose that you detect an issue with your microscope. Sending an error report over to our dedicated team of service engineers can give them a head start in fixing your issue. With this report, they can rapidly hone into a specific component that may be malfunctioning and ask more relevant, specific questions to help troubleshoot the issue.

Having an overview of the entire microscope’s performance in a single report, as opposed to gathering information from a mix of separate analytical tools, can save the user time and money. The service engineer can determine the problem quickly so users can get back to their work. In fact, a detailed overview in a succinct report increases the likelihood that our engineers can fix a problem remotely, enabling users to return to their research with minimal instrument downtime.

We’ve already seen many of our customers benefit from universal troubleshooting instruments that ensure the acquisition of reliable data, remove the bias introduced by the microscope, reveal how the system performance evolves over time, and help them get more from their quantitative microscopy.

Want help troubleshooting your microscope’s performance for quantitative analysis? Contact our dedicated customer support team here.

To learn more about Argolight's solutions, you can contact them here.

Related Content

6 Tips for Fluorescence Live Cell Imaging

Microscope Camera Best Practices for Fluorescence Imaging

Label-Free Quantification You Can Count On: A Deep-Learning Experiment